Product Introduction

Butterfly valves are pivotal in fluid control systems, renowned for their simplicity and ease of operation. They come in a variety of types, each tailored to specific applications. Here's a fresh look at the common classifications of butterfly valves and their roles:

1. **Specialized Butterfly Valves:**

- These valves are engineered for unique operational demands and environments. They are customized to excel in particular settings, such as high-temperature or corrosive media applications. Examples include temperature-controlled, high-pressure, and chemical-resistant butterfly valves.

2. **Electric Butterfly Valves:**

- Operated by an electric motor, these valves offer precise control over the flow. The motor actuates the valve disc, allowing for quick and accurate adjustments to fluid flow, ideal for processes requiring meticulous flow management.

3. **Pneumatic Butterfly Valves:**

- Controlled by pneumatic devices, these valves use compressed air or gas to drive the disc's rotation. Known for their swift response and reliable operation, they are suited for applications with frequent cycling.

4. **Manual Butterfly Valves:**

- Relying on manual operation, these valves are straightforward and user-friendly. They are perfect for small-scale flow control or as a backup in emergency situations where automated systems may fail.

5. **Eccentric Butterfly Valves:**

- Characterized by a stem offset from the seat's center axis, these valves reduce wear and friction. They require less torque to operate, making them suitable for flow regulation and shut-off in various mediums.

6. **Double Eccentric Butterfly Valves:**

- Offering superior sealing to their single eccentric counterparts, these valves feature a stem and disc axis that do not align with the seat's center. This design ensures minimal contact during operation, enhancing sealing performance and making them ideal for applications demanding high sealing integrity and a wide range of flow control.

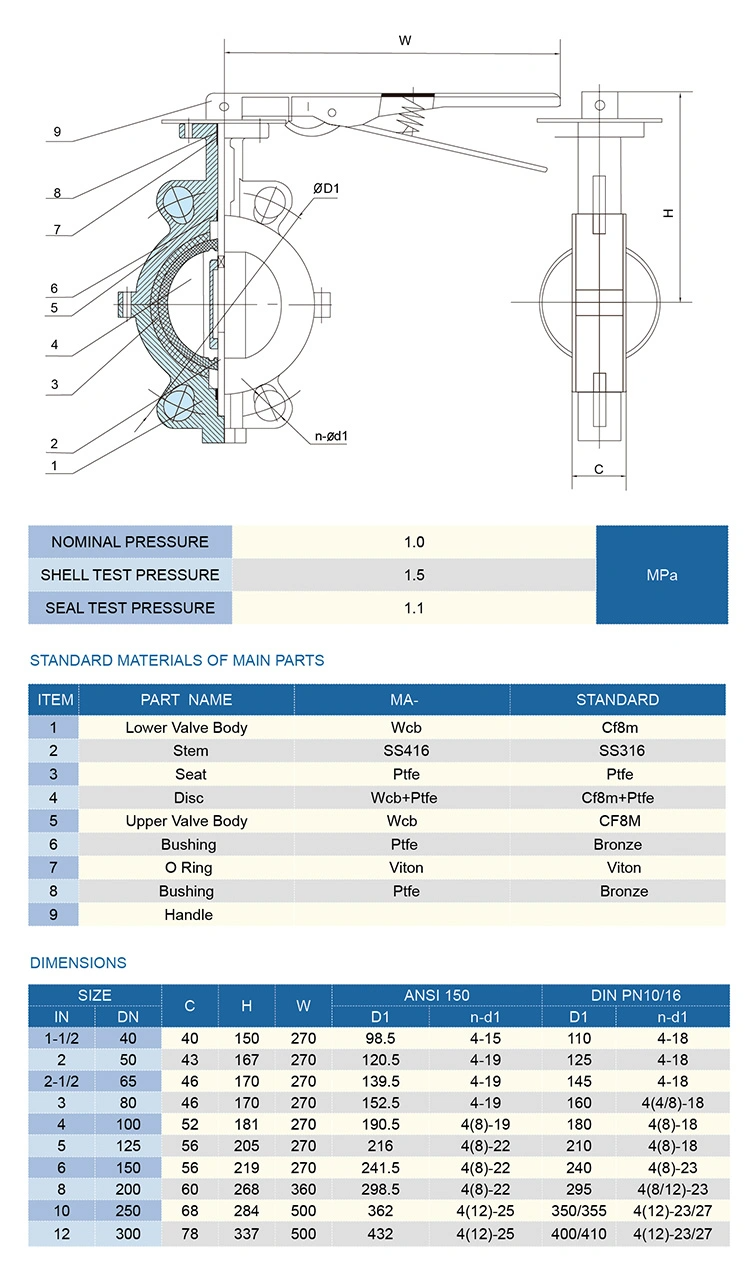

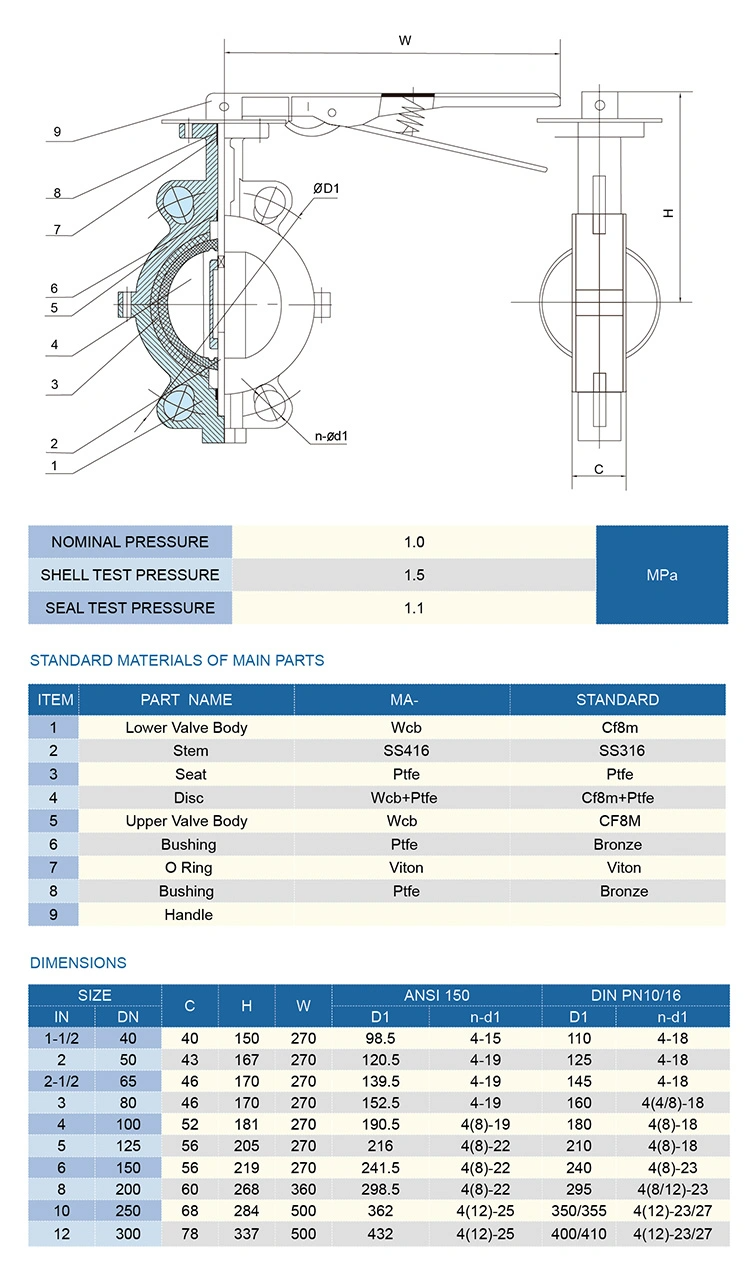

Product Data

Production Process

Technical Parameter

Name: | Customized Lost Wax Casting Precision Casting Valve Body |

Material: | stainless steel, carbon steel, alloy steel and so on. |

Designs: | 1. As per customer's drawing |

2. As per customer's samples | |

Surface Treatment: | 1. Polish |

2. Sand blasting | |

Service: | OEM service available |

Products: | All kinds of stainless steel casting: include pipe fitting, valve part, |

Advantages: | Experienced to machine casting parts |

Near to Ningbo port | |

3. We provide: OEM stainless steel lost wax castings |

Product Display

Quality inspection equipment

Packaging & Shipping

FAQ

1. What is the Minimum Order Quantity?

5~1000 pcs.And we also accpet sample orders.

2. Can you manufacture according to customer's samples?

According to samples, we can make drawing, tooling and sample

3.How long will it take to make new samples according to customer's drawing or sample?

Totally 20 days. 10 days for tooling and another 10 days for sample.

Product Introduction

Butterfly valves are pivotal in fluid control systems, renowned for their simplicity and ease of operation. They come in a variety of types, each tailored to specific applications. Here's a fresh look at the common classifications of butterfly valves and their roles:

1. **Specialized Butterfly Valves:**

- These valves are engineered for unique operational demands and environments. They are customized to excel in particular settings, such as high-temperature or corrosive media applications. Examples include temperature-controlled, high-pressure, and chemical-resistant butterfly valves.

2. **Electric Butterfly Valves:**

- Operated by an electric motor, these valves offer precise control over the flow. The motor actuates the valve disc, allowing for quick and accurate adjustments to fluid flow, ideal for processes requiring meticulous flow management.

3. **Pneumatic Butterfly Valves:**

- Controlled by pneumatic devices, these valves use compressed air or gas to drive the disc's rotation. Known for their swift response and reliable operation, they are suited for applications with frequent cycling.

4. **Manual Butterfly Valves:**

- Relying on manual operation, these valves are straightforward and user-friendly. They are perfect for small-scale flow control or as a backup in emergency situations where automated systems may fail.

5. **Eccentric Butterfly Valves:**

- Characterized by a stem offset from the seat's center axis, these valves reduce wear and friction. They require less torque to operate, making them suitable for flow regulation and shut-off in various mediums.

6. **Double Eccentric Butterfly Valves:**

- Offering superior sealing to their single eccentric counterparts, these valves feature a stem and disc axis that do not align with the seat's center. This design ensures minimal contact during operation, enhancing sealing performance and making them ideal for applications demanding high sealing integrity and a wide range of flow control.

Product Data

Production Process

Technical Parameter

Name: | Customized Lost Wax Casting Precision Casting Valve Body |

Material: | stainless steel, carbon steel, alloy steel and so on. |

Designs: | 1. As per customer's drawing |

2. As per customer's samples | |

Surface Treatment: | 1. Polish |

2. Sand blasting | |

Service: | OEM service available |

Products: | All kinds of stainless steel casting: include pipe fitting, valve part, |

Advantages: | Experienced to machine casting parts |

Near to Ningbo port | |

3. We provide: OEM stainless steel lost wax castings |

Product Display

Quality inspection equipment

Packaging & Shipping

FAQ

1. What is the Minimum Order Quantity?

5~1000 pcs.And we also accpet sample orders.

2. Can you manufacture according to customer's samples?

According to samples, we can make drawing, tooling and sample

3.How long will it take to make new samples according to customer's drawing or sample?

Totally 20 days. 10 days for tooling and another 10 days for sample.