* * Product Introduction :* *

- ** Definition :** Flange type high temperature steam valve is an important device for regulating steam speed and steam volume. It controls the steam flow by adjusting the valve opening and is designed to withstand and operate reliably in high temperature environments.

Material selection is

Cast steel, stainless steel (304, 304L, 316, 316L), carbon steel, alloy steel (12Cr1MoV, 15CrMo)

Selecting the right material is crucial to ensure the performance and longevity of flanged high temperature steam valves. The design needs to consider the valve's working pressure, working temperature, medium characteristics and expected service life and other factors.

** Technical parameters and selection :**

** When selecting a high temperature steam valve, consider the maximum operating temperature, pressure, flow rate and material to ensure that the valve's performance meets the specific application needs. Options include pneumatic, electric or manual control systems, each with the right accessories for optimal operation.

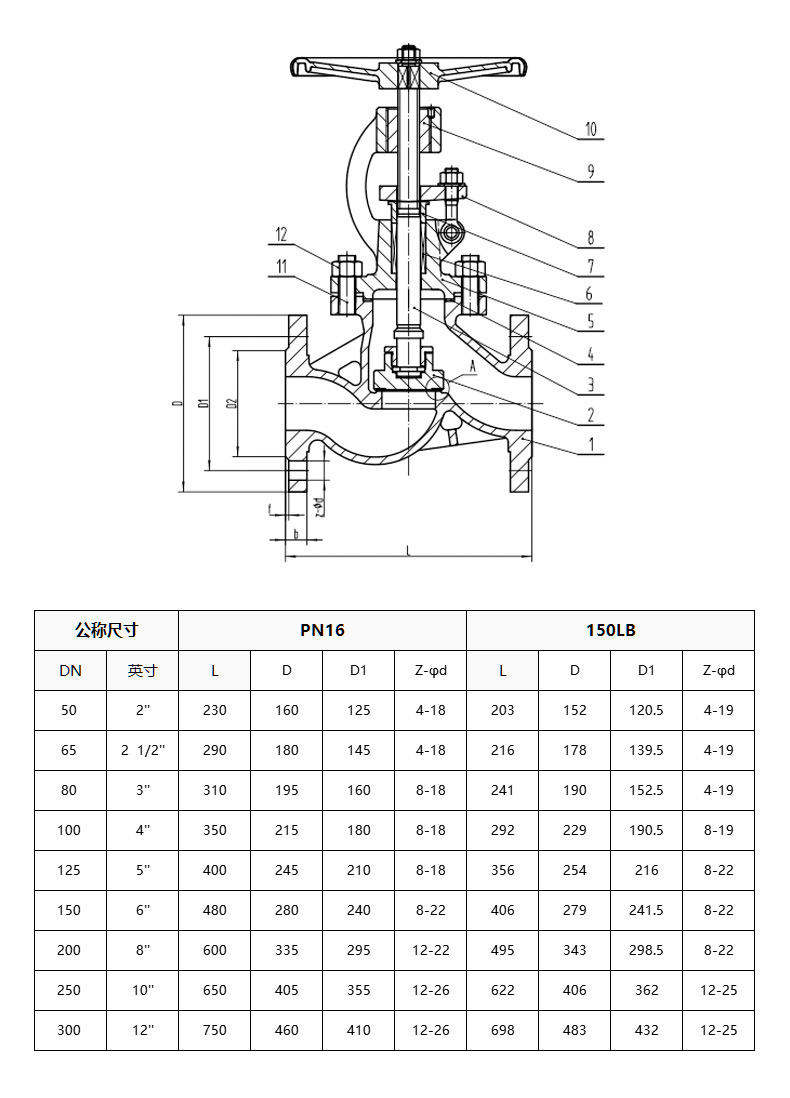

Name | Product model | Nominal diameter | Body material | Application field |

Flange connection high temperature steam valve | J41W-16P/150LBP | DN50-DN300 | Stainless steel 304 | Water treatment, petrochemical, food and medicine, power energy, metallurgy, etc |

Note: The configuration of each part of this product is optional, please consult us for details, explain your specifications and requirements.

The above information is for reference only, Zhejiang Tieyong Machinery Manufacturing Co., Ltd. reserves the right to update the design, if you have any questions, please consult customer service.

2 Product Advantages

|

Valve body The body is precision casting body, secondary shot blasting treatment, fine appearance, no trachoma |

Bonnet and stem The contact between the valve cover and the valve stem should be sealed backwards to prevent leakage |

|

|

Surface treatment The surface of the valve body is pickled and passivated to make the casting appearance a uniform silver self-bright color and maintain the metallic luster |

Two-layer detection Each valve is manufactured in accordance with national standards for shell and seal double-layer pressure testing |

|

3.Technical parameter

Connection form | Francois | material | Stainless steel | Nominal diameter | DN100 (mm) |

Applicable medium | steam | Pressure environment | High tension | Operating temperature | hyperthermia |

Standard | National standard | appearance | minitype | Flow direction | unidirectional |

Driving mode | Manual operation | Parts and accessories | actuator | form | Plunger type |

Type (channel location) | Straight-through type | 3C Valve Category | industry | specification | DN25,DN32,DN40,DN50,DN100,DN150,DN200,DN250,DN300,DN350 |

4. Quality inspection equipment

Complete testing equipment to ensure product quality.

5.Packaging & Shipping

6. FAQ

1. What is the Minimum Order Quantity?

5~1000 pcs.And we also accpet sample orders.

2. Can you manufacture according to customer's samples?

According to samples, we can make drawing, tooling and sample

3.How long will it take to make new samples according to customer's drawing or sample?

Totally 20 days. 10 days for tooling and another 10 days for sample.