Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Image Source: pexels

You cast aluminum parts by melting aluminum in a foundry and pouring it into a mold to form the desired casting part. Casting is essential in manufacturing because it lets you create complex shapes and strong parts with less waste.

Preparation and safety matter at every step, especially for beginning metal-casters working with molten aluminum.

Aluminum casting stands out for its lightweight, high strength-to-weight ratio, and excellent thermal conductivity, making cast aluminum ideal for automotive, machinery, and energy applications.Zhejiang Tieyong Machinery Manufacturing Co., Ltd. delivers reliable casting parts solutions and supports foundry professionals with expert casting techniques.

Casting aluminum parts involves melting aluminum and pouring it into molds to create strong, lightweight parts with complex shapes.

Safety is crucial: always wear heat-resistant gear and keep water away from molten aluminum to prevent accidents.

Choose the right casting method based on your needs: die casting for high-volume precision, investment casting for detailed shapes, and sand casting for large or simple parts.

Proper mold making, controlled melting and pouring, and careful cooling improve the quality and strength of cast aluminum parts.

Finishing techniques like anodizing, powder coating, and polishing protect parts and enhance their appearance for different uses.

You create a casting part by pouring molten metal, such as aluminum, into a mold. The metal cools and hardens, taking the shape of the mold. This process lets you make parts with complex shapes that would be hard to form by cutting or machining. Aluminum casting stands out because it uses aluminum’s low melting point, about 660 °C, which makes melting and molding easier than with many other metals. You can add elements like silicon, magnesium, or copper to aluminum. These elements improve fluidity, strength, and corrosion resistance. When you use aluminum for casting, you get parts that are lightweight, strong, and resistant to rust. Zhejiang Tieyong Machinery Manufacturing Co., Ltd. produces casting parts like valves, pump impellers, and car accessories using advanced aluminum casting methods.

Tip: Aluminum’s low density (2.7 g/cm³) makes it much lighter than steel, so you can use it for parts where weight matters.

Aluminum casting also helps you save material and cost. You can form a casting part in one step, which reduces waste and speeds up production. The process works well for both small and large parts, from tiny electronic housings to big engine blocks.

You find cast aluminum parts in many industries because of their unique properties. The table below shows where you might see cast aluminum used:

| Industry Sector | Common Cast Aluminum Applications |

|---|---|

| Automotive | Engine blocks, transmission housings, alloy wheels, suspension components, electric vehicle casings |

| Aerospace and Aviation | Pump housings, valve bodies, instrument enclosures, landing gear components, heat exchangers |

| Consumer Electronics & Appliances | Laptop/smartphone casings, TV frames, heat sinks, internal brackets, household appliances (blenders, fans, mixers) |

| Industrial Machinery | Gearbox housings, pump bodies, compressor frames, motor casings, conveyor components |

| Renewable Energy & Electric Infrastructure | Solar panel mounts, wind turbine enclosures, battery frames, charging station casings |

| Architecture & Building Systems | Lighting fixtures, balustrades, facade panels, custom trims |

| Emerging Sectors | Electric vehicle battery enclosures, additive manufacturing molds, robotics parts |

You can use aluminum casting to make parts for cars, planes, electronics, and even renewable energy systems. Cast aluminum gives you a high strength-to-weight ratio, good corrosion resistance, and the ability to create detailed shapes. These features make cast aluminum a top choice for modern manufacturing.

Image Source: pexels

Casting aluminum parts involves several important steps. You need to follow each step carefully to get strong, high-quality parts. This process works in both small workshops and large foundries. Here is a step-by-step guide to help you understand how to cast aluminum parts safely and efficiently.

Before you start, you must prepare your workspace and gather all the tools. Preparation helps you avoid mistakes and keeps you safe. If you want to build a foundry at home or in a workshop, you need to plan each step.

Assembling the furnace: Set up your furnace in a dry, well-ventilated area. Make sure the floor is free from moisture. Moisture can cause explosions when it touches molten aluminum.

Gathering safety gear: Wear personal protective equipment. Use aluminized clothing, heat-resistant gloves, face shields, and protective sleeves. These protect you from heat, splashes, and dust.

Inspecting equipment: Check your tools and furnace before operating the furnace. Make sure everything works well to prevent accidents.

Training and awareness: Learn how to recognize heat stress. Make sure you and your team know all safety rules.

Controlling the environment: Keep the foundry clean and control dust and noise. This helps you stay alert and safe.

Tip: Always keep water away from molten aluminum. Even a small drop can cause a dangerous reaction.

Making the mold is a key part of the casting process. The mold shapes the final part. You can use different materials for molds, such as green sand, steel, graphite, or ceramic. Each material has its own benefits. Green sand is cheap and reusable, but steel molds give you more detail and last longer.

To make a mold, you first create a master pattern. You can use wax, wood, or plastic for this pattern. Place the pattern in a mold box and pack heat-resistant sand around it. Remove the pattern to leave a cavity. Cut channels for pouring the mold and for air to escape. Apply a release agent to the mold surface to stop the aluminum from sticking.

Note: You are required to make mold materials that can handle temperatures above 660°C. Always use safety gear when making the mold.

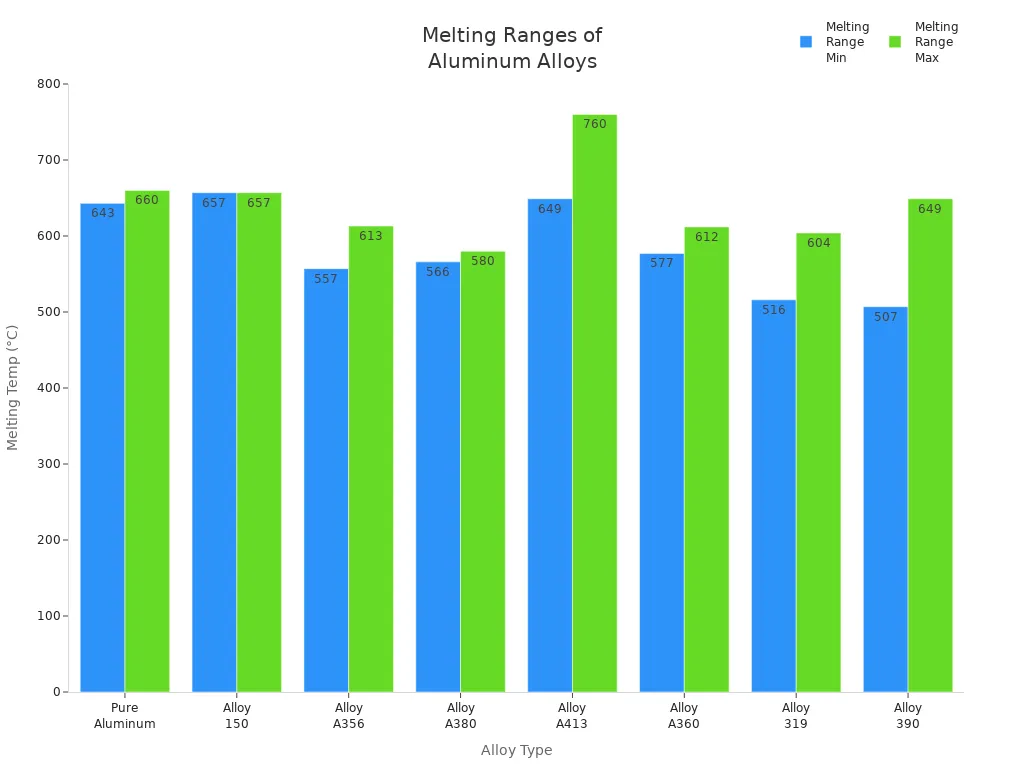

Melting aluminum is the next step. You need to heat the metal until it becomes liquid. Most aluminum melts at about 660°C, but alloys can melt at different temperatures. The best pouring temperature is between 680°C and 700°C. This range gives you a smooth surface and fills the mold well.

| Alloy Type | Melting Temperature Range (°C) |

|---|---|

| Pure Aluminum (99.0% - 99.96%) | 643 - 660 |

| Alloy 150 | ~657 |

| Alloy A356 | 557 - 613 |

| Alloy A380 | 566 - 580 |

| Alloy A413 | 649 - 760 |

| Alloy A360 | 577 - 612 |

| Alloy 319 | 516 - 604 |

| Alloy 390 | 507 - 649 |

When operating the furnace, heat the aluminum slowly and remove any impurities from the surface. Use a crucible to hold the molten metal. When you pour the aluminum, do it slowly and steadily. This reduces turbulence and stops air from getting trapped. You can use ceramic filters to catch impurities. If you want to build a foundry for aluminum die casting, you may use machines that inject metal under pressure for better results.

Tip: Keep the pouring height low to avoid splashing and dross. Calm, steady pouring gives you better cast aluminum parts.

After pouring, let the aluminum cool and solidify. Cooling time depends on the mold material, part thickness, and temperature. Sand molds cool slower than metal molds. Thin parts cool faster than thick ones. If you use chills or insulation, you can control the cooling speed.

Thick sections take longer to cool.

Inside corners cool slower than outside corners.

The starting temperature of the molten metal affects cooling time.

Airflow and room temperature also change how fast the part cools.

When the part is solid, remove it from the mold. Use ejector pins or gentle tapping for metal molds. For sand molds, break the mold apart. Handle the hot part with care.

Note: Fast cooling can make the part stronger, but it may also cause warping. Always plan your cooling process for the best results.

Finishing gives your cast aluminum parts a smooth, strong surface. You need to trim off extra metal, such as gates and risers. Use tools like grinders or saws. After trimming, you can polish, paint, or coat the part.

| Finishing Method | Description & Process | Benefits for Surface Quality |

|---|---|---|

| Anodizing | Electrochemical process creating an oxide layer; Types I (thin), II (thicker), III/hardcoat (thickest) | Enhances corrosion resistance, scratch resistance, durability |

| Electroplating | Deposits a thin metallic coating via electrolytic bath; includes chrome plating (hard and decorative) | Improves aesthetics, corrosion resistance, wear resistance |

| Powder Coating | Electrostatic application of dry powder followed by heat curing | Produces high-quality, flexible, scratch-resistant finishes |

| Polishing | Abrasive treatment involving roughing, polishing, brightening, and protection | Improves shine, smoothness, and surface luster |

Other finishing options include PVD coating, painting, passivation, shot blasting, and electrophoresis. Choose the finishing method based on where you will use the part. For example, anodizing works well for outdoor parts, while powder coating gives a tough, colorful finish.

If you need precise shapes, you can use machining cast aluminum parts after casting. This step helps you get the exact size and surface you want.

Tip: Always finish your parts to improve their look and protect them from rust and wear.

Image Source: unsplash

When you use the sand-cast aluminum method, you start by making a mold from sand. This mold shapes the metal as it cools. Sand molds are popular in casting because they are easy to shape and cost less than metal molds. You can use different materials to build a strong mold. The table below shows what you need:

| Material Category | Types / Examples | Description / Role |

|---|---|---|

| Base Sand | Silica sand, Olivine sand, Chromite sand, Zircon sand, Chamotte sand | Forms the mold cavity; chosen for melting point and finish. Silica is most common. |

| Binder | Clay (bentonite, kaolinite), Resin, Sodium silicate | Holds sand together and gives strength. Clay is common in green sand. |

| Additives | Coal powder, Fuel oil | Improves finish and reduces defects. |

| Parting Compounds | Talc, graphite, mineral oil | Helps separate the mold from the pattern. |

You pack the sand around a pattern, then remove the pattern to leave a cavity. You add channels for the molten metal to flow in and for air to escape. You can use green sand, which is sand mixed with clay and water, for most casting jobs.

Pouring is a key step in sand-cast aluminum casting. You need to pour the molten metal carefully to avoid defects. Here is how you do it:

Prepare a strong mold by packing the sand tightly.

Use sand with small grains and low permeability to stop metal from leaking.

Reinforce weak spots in the mold with nails or rods.

Clean the molten metal to remove impurities.

Control the temperature of the metal to prevent problems.

Coat the mold surface to protect against metal sticking.

Pour the molten metal slowly and steadily to reduce air bubbles.

Tilt the mold if needed for smooth flow.

Fill the mold in one go to avoid uneven cooling.

Use channels to guide the metal and let air escape.

Tip: Pouring slowly and using the right mold setup helps you get better casting results.

Sand-cast aluminum casting gives you many benefits, but you should know its limits. The table below compares the main points:

| Aspect | Sand Casting Advantages | Sand Casting Disadvantages |

|---|---|---|

| Mold Material | Easy to change and low cost | Rough surface finish |

| Material Compatibility | Works with many metals, including aluminum | Lower accuracy and looser tolerances |

| Cost | Cheaper patterns and molds | More defects like shrinkage or gas bubbles |

| Production Volume | Good for small batches and prototypes | Not ideal for very precise or tiny parts |

| Part Size | Can make very large castings | Harder to make thin or complex shapes |

| Production Speed | Simple process, but slower than die casting | Longer time per part |

You can use sand-cast aluminum casting for large parts, prototypes, or when you need flexibility in design. This method works well for many industries, such as automotive and machinery, where you need strong, custom parts at a lower cost.

You use die casting when you want to make strong, detailed aluminum parts quickly. In the aluminum die casting process, you inject molten aluminum into steel molds under high pressure. This method gives you parts with smooth surfaces and tight tolerances. You can make thousands of identical parts, such as car engine blocks or electronics casings, in a short time. Die casting works well for both small and large components. You get high strength, durability, and excellent corrosion resistance. The process also reduces material waste and supports rapid production cycles. Many industries choose aluminum die casting for mass production because it saves time and money.

| Feature / Benefit | Description |

|---|---|

| Flexibility | Makes small and large parts, from electronics to automotive. |

| Improved Mechanical Properties | High strength and wear resistance from fine-grained structure. |

| Integration of Multiple Features | Complex shapes with threads, holes, and passages in one casting. |

| Superior Surface Finish | Smooth surfaces need little finishing. |

| High Strength-to-Weight Ratio | Lightweight and strong, ideal for cars and planes. |

| Cost-Effective for Mass Production | Fast cycles and mold reuse save money. |

| Excellent Corrosion Resistance | Natural oxide layer protects parts. |

| Good Thermal and Electrical Conductivity | Great for heat sinks and housings. |

| Reduced Material Waste | Efficient mold filling means less scrap. |

| Faster Production Cycle | Quick solidification allows high-volume orders. |

| Versatility with Part Sizes | Handles simple or complex shapes, big or small. |

You use investment casting when you need very precise aluminum parts with complex shapes. This method starts with a wax pattern that matches your part. You dip the pattern in ceramic slurry and coat it with sand. After repeating this step, you melt out the wax, leaving a hollow ceramic mold. You pour molten aluminum into the mold, let it cool, and then break away the ceramic shell. Investment casting gives you parts with excellent surface finish and high dimensional accuracy. You can make thin walls and intricate details. This process suits aerospace, medical, and energy industries where precision matters most.

Assemble wax patterns onto a runner.

Pour molten aluminum into the mold.

Let the metal cool and solidify.

Break away the ceramic shell.

Cut off the parts and finish them.

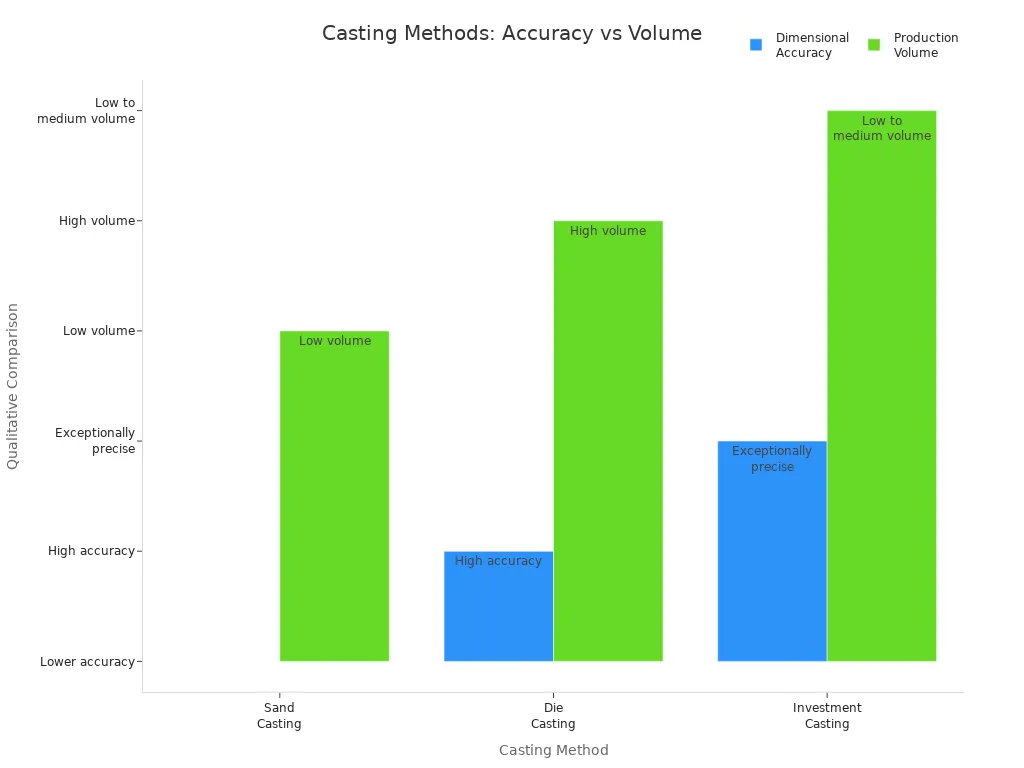

You can choose between die casting, investment casting, and sand casting based on your needs. Die casting is best for high-volume production and parts that need tight tolerances. Investment casting works well for low to medium volumes and parts with complex shapes. Sand casting is flexible and cost-effective for large or simple parts but has rougher surfaces and lower accuracy.

| Casting Method | Dimensional Accuracy | Surface Finish | Production Volume Suitability | Mold Type | Notes on Production Cost and Complexity |

|---|---|---|---|---|---|

| Sand Casting | Lower accuracy; rougher surface finish | Rough surface | Suitable for low production volumes; quick mold prep and low tooling cost | Sand molds | Versatile for large parts; less precise; requires more finishing |

| Die Casting | High dimensional accuracy; uniform design | Excellent surface finish | Ideal for high volume production runs | Reusable metal dies | High tooling cost; less post-processing needed; best for non-ferrous metals |

| Investment Casting | Exceptionally precise and accurate | Exceptional surface finish | Best for low to medium production volumes | Disposable ceramic molds | Suitable for complex geometries and thin walls; minimal post-processing |

Tip: If you want high-precision aluminum parts in large quantities, choose aluminum die casting. For complex shapes and lower volumes, investment casting is the best method. Sand casting is great for big, simple parts or prototypes.

Zhejiang Tieyong Machinery Manufacturing Co., Ltd. uses advanced aluminum die casting and investment casting techniques to deliver reliable, high-quality casting solutions for many industries.

When you work with casting, you may face several common defects. These problems can affect the quality of your finished parts. Knowing what to look for helps you prevent issues before they become serious.

| Defect | Typical Causes |

|---|---|

| Porosity | Gas trapped during solidification, moisture in mold, poor venting |

| Cold Shuts | Improper temperature control, slow pouring, turbulence |

| Misruns | Low pouring temperature, slow speed, complex mold design |

| Shrinkage | Volume reduction during cooling, uneven cooling in thick sections |

| Inclusions | Dirty molds, poor filtering, low-quality raw materials |

| Hot Tears | High thermal gradients, mold restricting contraction, wrong alloy selection |

| Surface Cracks | Rapid cooling, thermal shock, stress concentration |

| Flash | Improper mold clamping, excessive pouring pressure, misalignment |

| Blistering | Gas trapped inside, inadequate venting, excessive moisture |

| Sand Holes | Loose sand particles, poor sand quality, improper compaction |

You may also see warping or distortion. This often happens when cooling is too fast or uneven. Mold design, gate placement, and cooling channels all play a role. Porosity can result from trapped gas or shrinkage during cooling. If you notice these defects, check your melting and pouring practices, mold preparation, and cooling process.

Tip: Regular inspection and careful control of each casting step help you catch defects early and improve part quality.

You can achieve high-quality casting by following proven methods. Start with a clean, well-maintained mold. Preheat the mold to reduce thermal shock and promote even cooling. Use simulation software to predict and avoid warping before you begin production. Design your parts with uniform wall thickness and smooth transitions to reduce stress.

Maintain molds and check alignment often.

Use controlled cooling techniques for even solidification.

Place gates carefully to guide molten metal and avoid turbulence.

Apply heat treatment, such as annealing or solution treatment, to improve strength and durability. For example, T6 heat treatment can raise tensile strength and hardness, making your parts last longer.

Inspect each part using visual checks, mechanical tests, and dimensional measurements. Tools like CMMs and digital comparators help you confirm that your casting meets strict quality standards.

When you finish casting, consider machining cast aluminum parts for precise dimensions and a smooth surface. This step ensures your parts fit perfectly in their final application.

Note: Many industries require certifications like ISO 9001 or IATF 16949 to guarantee casting quality. Meeting these standards shows your commitment to reliable, high-performance parts.

Casting requires careful planning, safety training, and the right method for your project. You should always use personal protective equipment, keep tools dry, and follow strict casting procedures.

Ongoing training, equipment checks, and safety audits help prevent casting accidents.

Choose a casting provider with quality certifications, strong customer support, and proven experience.

If you want to learn more about casting, explore resources from the Metal Casting Institute, THORS, or the American Foundry Society. For reliable casting solutions, Zhejiang Tieyong Machinery Manufacturing Co., Ltd. offers expert support.

You should look at part size, shape, and production volume. Die casting works best for high-volume and precise parts. Sand casting suits large or simple shapes. Investment casting helps you make complex, detailed components.

You need heat-resistant gloves, a face shield, aluminized clothing, and sturdy boots. These protect you from splashes and high temperatures. Always keep water away from molten metal.

Yes, you can melt scrap aluminum and use it for new parts. Recycling saves energy and reduces waste. Make sure you clean and sort scrap before melting.

You should control pouring speed and temperature. Use clean molds and filters. Remove moisture from sand and keep the workspace dry. Inspect parts for defects after cooling.

| Finishing Option | Benefit |

|---|---|

| Anodizing | Corrosion resistance |

| Powder Coating | Durable color finish |

| Polishing | Smooth, shiny surface |

You can choose a finishing method based on your part’s use and desired look.